- Articles ›

- Operations and IT ›

- Green Production – Competitive Advantage For Next Decade Articles

Green Production – Competitive Advantage For Next Decade

Green Production is a part of green business strategies that are based on the principle of environmental sustainability. It focuses on profitability through environmentally friendly operating processes. These processes may constitute a key basis for competitive advantage in the coming decades. It is not just instituting pollution controls or recycling programs when manufacturing goods but it is about minimizing the harmful impact of the manufacturing processes on the environment at every stage. According to Hart and P.Shirvastav, Green production focuses on three fundamental goals

- Minimize emissions, effluents, and accidents

- Minimize the use of virgin materials and non-renewable forms of energy

- Minimize the life-cycle cost (cradle to grave) of products or services.

Green production is based on the concept of sustainability; Sustainability is one’s ability to meet society’s present needs without compromising the ability of future generations to meet their own needs.

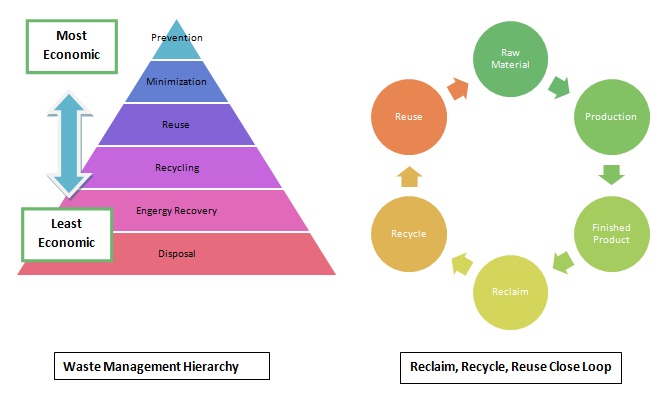

Brief History of 3R’s & 3R’s Hierarchy:

The concept of 3R’s came into existence in the aftermath World War II, when there was dearth of materials. Initially the concept was implemented to help companies stay afloat in hard times when resources were limited. Later on the concept of 3R’s grew in popularity as many countries began shifting towards policies related to the environment. The United States created EPA (Environmental Protection Agency) in 1970 with the intent to monitor environmental activity. Many international Standards like Kyoto Protocol, Carbon Markets, ISO4001 and the Copenhagen Accord have come into existence.

- Reduce: It the first and most important step which calls for a proactive stance in purchasing. It also includes using only what is necessary in order to be aware of one’s supply stream and to minimize raw materials consumption

- Reuse: This step focuses on finding an alternative use for materials that would otherwise be considered waste and ultimately disposed of. The goal here is to eliminate wastage of materials

- Recycle: This step focuses on separating and distributing materials which cannot be reduced or reused so that can be sent to proper facilities to be recycled

While historically the waste hierarchy has been centrally focused on the 3 R’s, the following additional steps have been added

- Avoidance: It challenges an individual and organization to precisely calculate and purchase only what is absolutely necessary and avoid obtaining any materials that are not essential and could ultimately be wasted or passed along to the next steps in the hierarchy.

- Recovery: It entails extracting materials or energy from waste to be used or processed. An example would be reducing waste materials to compost.

- Treatment : It is subjecting waste to any physical, chemical or biological processes intended to change its volume or character, so that it can be disposed of with minimal effect on the environment

- Disposal: It is the final step and least preferred in the hierarchy

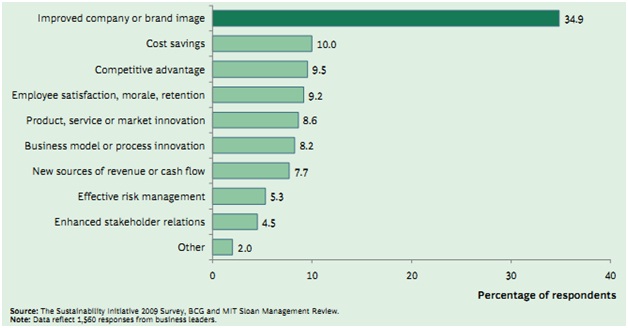

Drivers of Green Production - Improved Brand Image top concern driving Green:

More and more companies have started adopting Green Production as an integral part of their Operations. Factors driving such initiatives are

- Increasing energy and input costs

- Growing consumer awareness about Green Products

- Regulatory pressures

- Need to differentiate from competitors by enhancing competitive advantage

The chart below shows result of survey conduted by BCG in collaboration with CII. The survey aimed at finding drivers for green production

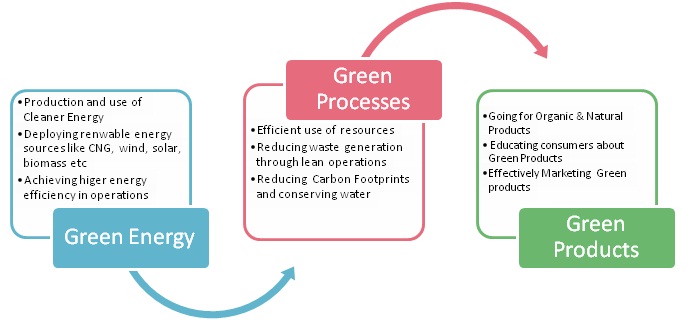

Techniques for Green Production

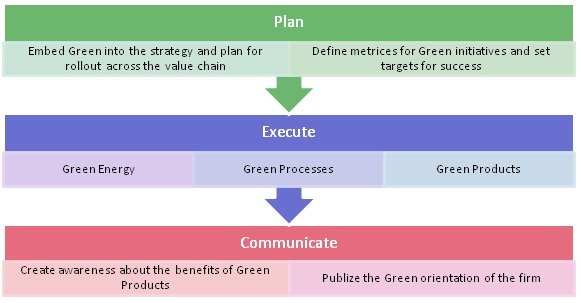

Manufacturing companies can address adopt Green Production by focusing in three areas

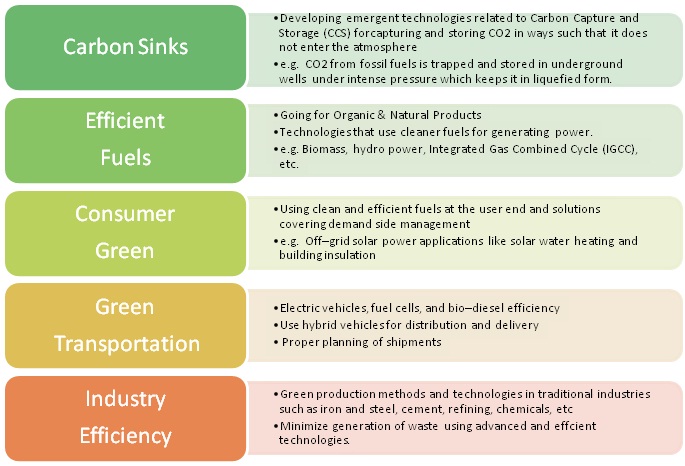

Technologies for Green Manufacturing

Companies should move towards new and emerging technologies that aid in making traditional businesses greener and creating new innovative green business models. The figure below lists technologies used for reducing GHG. These technologies can be classified into five broad categories.

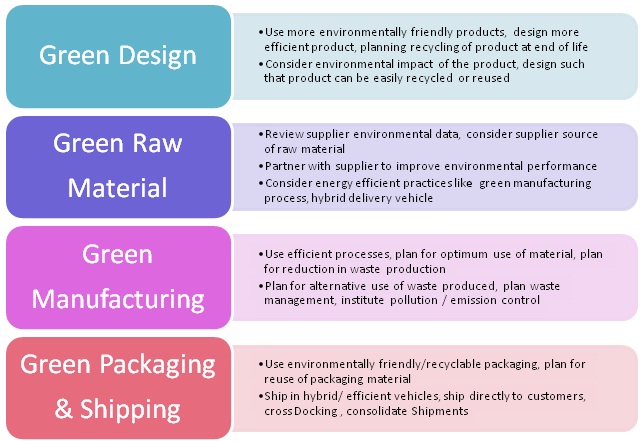

Green Supply Chain

To fully embrace Green Production and its benefits, an organization should adopt green policies and practices in the entire supply chain as depicted below

Framework for Green Production

Below are given few methods that can be used to achieve a complete green production goal.

Benefits of Green Production:

Companies that undertake Green initiatives reap advantages of brand enhancement, compliance to regulatory norms, have better reputation and greater ability to attract and retain talent, increase in customer retention and potential cost savings. However, these benefits can be reaped only after long term commitment to green production and manufacturing processes

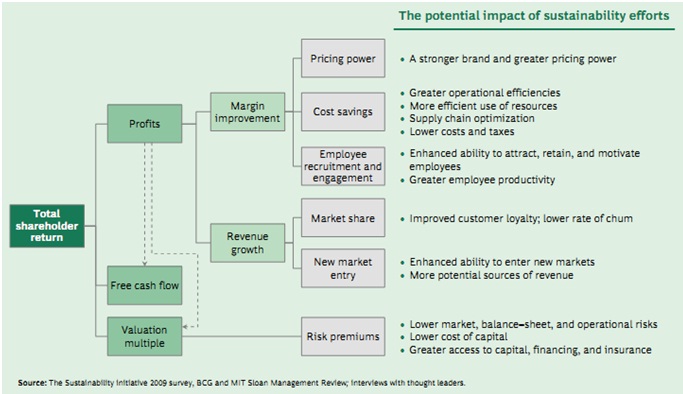

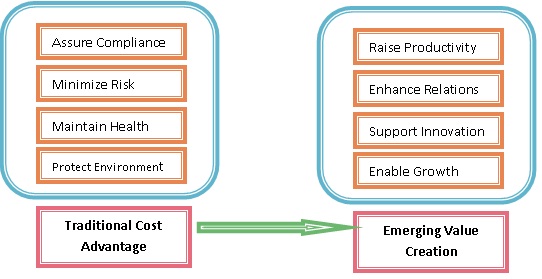

The diagram below shows specific areas where a company can leverage its green production processes

Green production takes care of both – Bottom line and Top line growth. The table below shows the various benefits achieved by adopting green production methods.

|

Stakeholders Interest |

Tangible Outcomes |

Intangible Value |

|

Employee Satisfaction |

Profitability |

Customer, Company, Reputation |

|

Environmental Sustainability |

Asset Utilization |

Alliance |

|

Community of Quality of life |

Service level |

Technology |

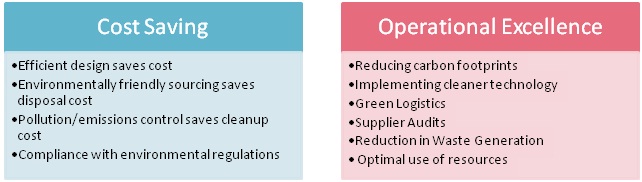

Adopting green production results in many advantages and cost savings in long run. The below table highlights some of these advantages

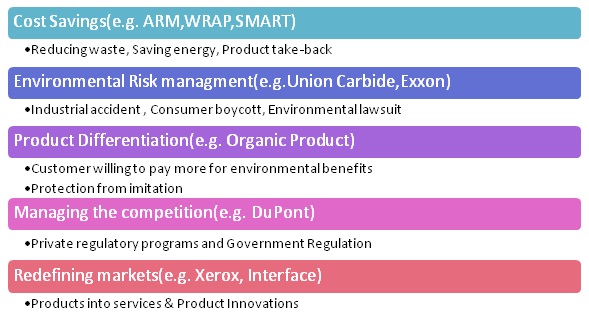

Moving from Traditional Cost advantage mode to Value creation across the Value chain

Companies following Green Production:

1. WALMART: The superstore has introduced many programs toward sustainability from 2005 onwards. It has implemented a process called “Sustainability 360”, which deals with all the aspects of its supply chain in sustainability efforts. It has found several different ways to implement policies that reduce waste and save money, and also benefiting the environment. It has set three long term goals of

- Supplied by 100% renewable energy

- Create zero waste

- Sell products that sustain resources and the environment

2. FORD : Ford makes vehicles, which are 85% recyclable by weight, more eco-friendly through increased use of renewable and recyclable materials; the 2010 Ford Taurus is the latest model to use eco-friendly bio-based seat cushions

- In 2009, Ford reduced the amount of automotive-related plastics to landfills by nearly 30 million pounds and saved approximately $4.5 million by reusing recycled materials

- Ford’s “reduce, reuse and recycle” commitments are part of its broader global sustainability strategy to reduce its environmental footprint

3. XEROX: Xerox’s commitment is to produce waste-free products in waste-free facilities to help customers reduce waste. Their goal is to design products, packaging and supplies that make efficient use of resources while minimizing waste, reusing material where feasible and recycling materials which can’t be reused. It recycles used Xerox cartridges & Equipment It has introduced programmers’ like Xerox supplies recycling program, Cartridge-free technologies and Waste-free factories

Green Production and India

According to the Ministry of Urban Development (Government of India), about 42 million metric tons of solid waste is generated per year in urban India with per capita waste generation rate ranging between 0.2 and 0.6 kg per day. The current practice of waste management in India is both formal as well as informal. Green production practices have just taken off in India and the Government of India has an important role to play in ensuring the early adaptation of green production technology across various sectors and companies.

The Central and State government have launched many initiatives like Solar Mission to promote Green Energy. The Department of Industrial Policy and Promotion has included promotion of Green Technology in its Draft Strategy. Still it’s a long run when India can fully embrace Green Production and be known as Green India!

References:

- http://www.enotes.com/small-business-encyclopedia/green-production

- http://www.metropolismag.com/story/20071017/clean-green-production-balancing-act

- http://corporate.ford.com/our-company/sustainability

- http://www.xerox.com/sustainability/green-products/enus.html

- http://walmartstores.com/sustainability/

- Sustainability Initiative 2009 Survey by BCG-CII

This article has been authored by Kiran Yadav and Lokesh Kumar from IIM, Indore.

Views expressed in the article are personal. The articles are for educational & academic purpose only, and have been uploaded by the MBA Skool Team.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us