- Articles ›

- Operations and IT ›

- Lean Culture: Importance And Execution Articles

Lean Culture: Importance And Execution

While pursuing MBA in operations, I was triumphed for getting selected in one of the leading manufacturing company of the world for my summer training. From the date of selection till joining, I was eagerly waiting for the day to come. And finally my wait was over. While sitting on the couch, waiting to meet my mentor anyone could have easily seen the alacrity and happiness on my smiling face.

Image: FreeDigitalPhotos.net

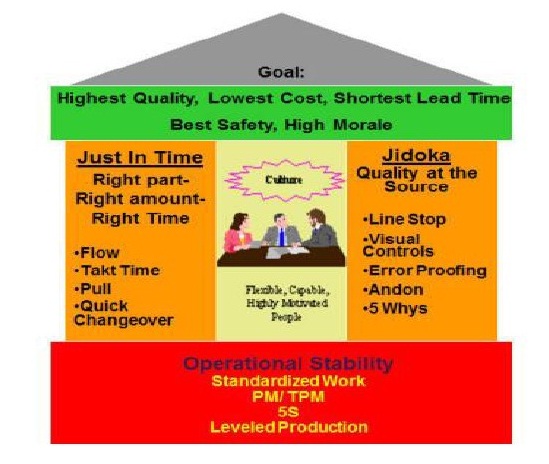

The project was to design Kanban between the work centers and warehouse. It is very common practice in manufacturing companies now to try implementing lean tools like Kanban. Toyota’s high cost cut in operations had attracted these companies to try implementing these lean tools. But it can only get implemented if it is supported by the culture of the organization. Thoroughly observing the Toyota production system it can be seen that Toyota has also given importance to the culture of the company.

REFERENCE Figure – Toyota Production System

Normal 0 false false false EN-IN X-NONE X-NONE MicrosoftInternetExplorer4

Lean culture is center of the pyramid, which links all other activities on one platform and that makes it very important for the purpose of implementing. But these manufacturing companies think that lean tools are the solution to every problem. They try to implement it without thinking of the culture of the organization.

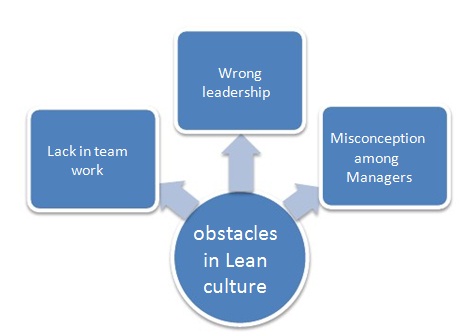

An organization’s culture dictates the attitudes of their people toward work and change. It dictates the relationships between people and departments. Lean culture helps an organization in obtaining correct leadership, proper team work and flexibility for change to introduce continuous improvement. In many companies like my internship company, there is absence of lean culture. The three main obstacles in adopting lean culture are lack in team work, wrong leadership and misconception among managers.

A. Lack in team work

Introducing change is difficult, if the employees of the involved department are not focusing on a single goal. Generally in manufacturing companies; three departments Production, Supply Chain and Quality are engaged in the production process. Supply Chain gives the production plan, Production follows that plan to produce finished goods and Quality makes sure that the quality of raw material and finished goods are maintained as per specifications. Therefore it is very important that these three departments work as a team. To implement lean tools, it is important that the team work between inter department should increase significantly.

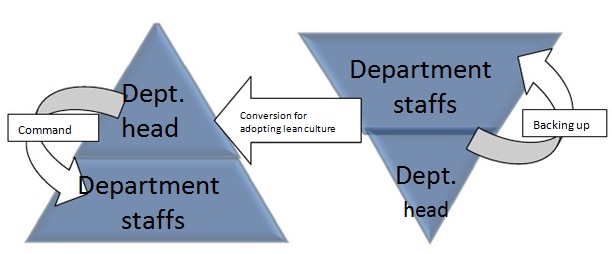

B. Wrong Leadership

One of the important factors for implementing lean culture is committed, lean-thinking leadership. But in many companies the top management is backing up their staffs, to show the intra-department team work. To implement lean successfully, a strong command and commitment is needed from them.

C. Misconception among Managers

Managers need to broaden their thinking towards lean. They only view one pillar of the Toyota production system, the lean tools to optimize the manufacturing process. But to implement these lean tools, it is important to adopt lean culture first. Because if the employees do not believe in lean culture and they are not adopting the culture then these lean tools will never get implemented. To implement lean, managers have to come out of their misconception and try to implement lean culture first.

Any company that wants to improve their manufacturing process can get benefited by adopting lean culture. Lean culture will help the employees to think lean, which will make it easy for the managers to implement different lean tools. While working on my project I came across many employees like project managers, Team leaders for whom it was hard to believe that Kanban can work. They all had a negative attitude towards the project and every time they meet me I had to convince them that it will work. This negative attitude was due to the absence of lean culture in the organization. They were not thinking in a lean prospective which can affect the implementation of the project. Therefore it is important to remove the above discussed obstacles to successfully adopt lean culture and implement lean tools in an organization. I am still hoping that my project will get implemented successfully and more importantly will sustain in the organization.

This article has been authored by Smit Rakesh from NITIE.

|

While pursuing MBA in operations, I was triumphed for getting selected in one of the leading manufacturing company of the world for my summer training. From the date of selection till joining, I was eagerly waiting for the day to come. And finally my wait was over. While sitting on the couch, waiting to meet my mentor anyone could have easily seen the alacrity and happiness on my smiling face. |

Views expressed in the article are personal. The articles are for educational & academic purpose only, and have been uploaded by the MBA Skool Team.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us