- Articles ›

- Operations and IT ›

- Supply Chain Risk during Natural Disasters Articles

Supply Chain Risk during Natural Disasters

A globalized world means intense competition and this scenario have led companies to focus on making their production and supply chains more optimized. Strategies like Just-in-Time, Lean and outsourcing have helped businesses to minimize cost and focus on core competencies .But these strategies have stretched their supply chain so businesses have become more vulnerable to the natural as well as man-made disasters.

Supply Chain and Disasters

Natural disasters such as the recent earthquake in China’s Sichuan province, the 2011 earthquake-induced tsunami or the recent Odisha cyclone in India capture the rapt attention of communities and businesses when they occur. Although they make the front pages, the relatively low probability can leave companies unprepared for their consequences. When companies are caught unprepared, natural disasters disrupt business: wrecking production, upending shipping schedules and impairing the ability to meet customers’ expectations for quality and timely service. In short, however optimized the company’s internal processes might be, natural calamities have the uncanny ability affect its performance.

However, a well prepared firm for disasters can benefit from it, though it is not directly affecting it and its supply chain. After 9/11 tragedy, US flags, lapel pins and other patriotic material became very popular. Unlike others, who fail to fulfill these demands, Wal-Mart using its real time demand tracker responded swiftly to the situation capturing the market. At the same time, Zara, a Spanish clothing retailer without much of ado, filled up its racks with black clothes in 5 days, against the normal lead time of 90 days.

Except a few firms, many do underestimate or simply ignore the events having disastrous effect on the supply chain they depend on and after-effects of this on their business. Although many of the firms consider this as new cost of doing the business, they fail to anticipate the non-monetary and unrecoverable losses to their businesses. The effect of supply chain disruptions prevails for much longer time, as long as two years, leaving negative effect on operating income, revenues as well as capacity utilization and efficiency. Toyota, after the devastating 2011 Japan earthquake, took almost a year to recover and get its production back to the full capacity. Apple too had to face the brunt of the quake. Hitachi which supplies electronic parts for the iPad and iPhones had to stop production due to power-cuts and equipment damage.

The risk is clear and real. Supply chain disruptions can have a cascading impact. Natural disasters, being rather unpredictable can reduce the time before the impact is felt. The good news though is companies still have tremendous opportunities to reduce these risks. Indeed, one may argue that companies have a responsibility to stakeholders to pursue such opportunities. The question that remains then is, how?

Dealing With Disruptions

Companies do purchase large insurance policies to guard against the risks. While some view these as the best measure, it can be argued that insurance is the last line of defense. Insurance can neither replace customers nor reputation. The risk-mitigation should be more holistic. Traditionally, companies have favored sites that are not historically prone to floods or storms. If companies follow such standards, they can choose suppliers that do the same. Easier said than done though, especially in the globalized world. Unfortunately, when companies outsource, they often unknowingly take on greater exposure to natural disasters.

Prevention is better than cure

Globalization though provides the solution. The answer is to separate the primary supplier and the alternate supplier. If a company sources electronic components from two suppliers in China’s quake-prone central provinces, the same quake can knock both out together. Something of this sort happened after Hurricane Katrina. Supply chains dependent on multiple suppliers based in New Orleans fell apart because the port was totally inundated. Hence, the idea should be alternate suppliers based in different regions, different electricity and raw material sources and preferably different transportation systems.

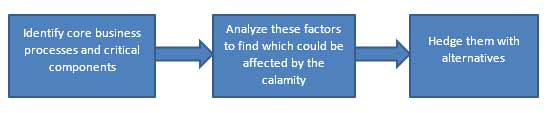

The most effective way to manage supply chain risks is to prevent them and, plan and prepare for the worst. Much of the work has to be done before the occurrence of the event. This begins with identification of key products, critical components, revenue drivers and core business processes in the supply chain- from supply of raw material to delivery of finished goods. After the analysis of all the factors in the supply chain, identify those which, if disrupted, could affect the business severely. Focus on these factor and hedge them with alternatives.

Another technique that has found value with companies is ‘Near Shoring’. Near shoring – sometimes referred to as reverse globalization, initially started to happen in 2009 as a way of shortening logistics networks. Increased wage rises in China followed by the recent natural disasters caused many companies to think about relocating manufacturing capacity back to their home market. For example Caterpillar moved production of their small bobcat excavator from Japan back to North America as a precaution against the frequent earthquakes.

Creating a Business Continuity Plan and keeping multiple supplier contracts can reduce the risks to a large extent. Testing the Plan can improve the preparedness. Addressing identified possible impacts can go a long way in making the chain resilient in the wake of the disaster.

Mitigation and damage control

When a catastrophe occurs, a quick response can minimize damage. The most critical part is to make the Business Continuity Plan operational. The focus must shift from concentrating on efficiency to ensuring business continuity is maintained. Quick decisions making is essential in situations like manufacturing at a supplier fails or the logistics are affected. Another important aspect is identifying which customers can be most effectively served. In other words, evaluating the cost-to-serve for different customer segments can help the company achieve its commitments. Nokia is the very good example known for responsiveness and agility in the event of crisis at supplier’s end. Philips, the only supplier of semiconductors to Nokia and Ericsson, till 2000, when fire broke in its plant in New Mexico. Nokia, being agile enough, find its way to get new suppliers without hampering its production. Ericsson relied on Philips and waited for the resumption of delivery, which eventually it did not get ended up losing $1.7 billion in the year, as well as huge loss of market share to Nokia.

Recovering from natural disasters

As the organization returns to normalcy in the wake of the disaster, it must realize which areas of its business have been exposed the most. Learning from the aftermath is imperative to plug the gaps in the Business continuity plan both at the strategic and operational levels.

A report outlining these can list failure points, cause and effect analyses and comparative study of industry peers have been able to do. Collect data from suppliers and customers to understand their viewpoints. Finally, improve information technology to better predict impact and also co-ordinate the insurance recoveries and future covers.

Benefits of supply-chain risk management v/s the costs

Risk mitigation techniques add cost. It will be costlier to employ backup operations centers, multiple supply routes and insurance. But the benefits outweigh these costs. Another point to note is if the firm has these alternative arrangements, the actual insurance premium might be less considering the lower risk profile of the company.

Benefits, not necessarily instantaneous but could be future oriented like invention of new product. In the Nokia example cited above, due to unavailability of specific chipsets from Philips, Nokia developed a model using generic chipsets, named Nokia 3310. This invention in low cost model became so popular that it ripped benefits to Nokia for years after the incident, capturing the market of low cost phones from Ericsson forever.

Implementation of holistic supply chain risk management program will uphold the commitment to good corporate governance and shareholders. A resilient and flexible supply chain is a must. Companies that don’t have it are really working without a ‘safety-net’. This, in the increasingly globalized world isn’t a smart idea.

The article has been authored by Pravin and Vishnu, K.J. Somaiya Institute of Management Studies and Research (SIMSR)

References:

- Bosman R. , “The New Supply Chain Challenge: Risk Management in the Global Economy”

- Rogers C. and Coulter J, CFO Research Services, “Preparing for the worst: Natural Disasters and Supply Chain risk management”

- Plenart G., Makharia M., Sambukumar R. Wipro Consulting, “Supply Chain Vulnerability in Times of Disaster”, Apics

Views expressed in the article are personal. The articles are for educational & academic purpose only, and have been uploaded by the MBA Skool Team.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us