- Articles ›

- Operations and IT ›

- Supply Chains in Disaster Management Articles

Supply Chains in Disaster Management

Recent rise in natural disasters such as earthquakes and hurricane as well as rise in terrorist activities has made disaster management and mitigation a necessity. In India alone about 60% of the landmass is prone to earthquakes, over 40 million hectares is prone to floods, 8% of the total area is prone to cyclones and 68% of the area is susceptible to drought. An average of about 4344 people lost their lives and about 30 million people were affected by disasters every year. A disaster, whether natural or man - made, brings up unforeseen challenges with respect to supply chain management perspective. We have experienced that in recent times major disasters have been followed by total disruption of supply chain system of disaster management. This is primarily due to unawareness of the top-level management about ground situation during disaster; resulting in bad decision making. We have looked at the factors which can help us to predict the amount of initial rescue effort required to start rescue operations. Also it proposes the flow of rescue material based on real-time pull based demand. The use and development of IT infrastructure and decision support systems is discussed. Also, paper contains ways in which private resources and logistic support can be used, building on the premise of better and efficient infrastructure provided by many service providers e.g. FedEx, Wal-Mart etc. The case in point is proven efficiency of Wal-Mart’s supply chain during Hurricane Katrina, which responded faster than rescue agencies and government rescue efforts and in the process saved many invaluable lives.

METHODOLOGY

There are multiple types of disaster and it becomes important to break it up in small components which are common. A case in example is maritime industry, wherein a master ship-disaster management plan is prepared to deal with all kind of emergencies. Plan of action is prepared basing the master model and it is further refined to meet the specific needs.

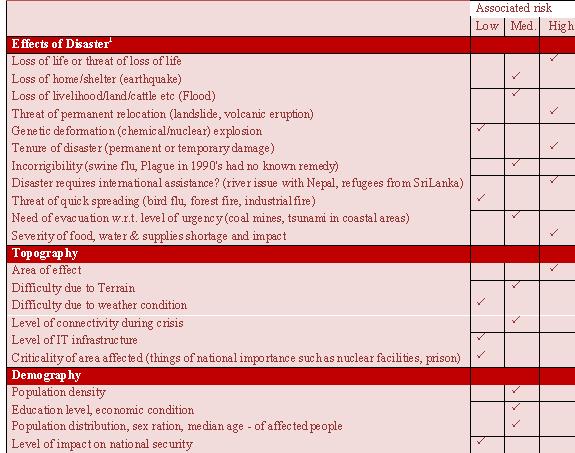

Our research paper aims at defining the requisite logistic and resources required to counter the disaster. The initial estimates of the requirements in our model will depend on three major factors degree of impact of disaster, topography and demography of the affected area. Later, as the real time data is gathered; the model will adjust the requirements required to bring in normalcy. Our model is a generalized model which could be applied on most of the presently faced disasters e.g. floods, earthquakes, cyclone, tsunami, volcanic eruption, landslide, terrorist attacks, fire etc. Corresponding need for supply chain capabilities will be outlined accordingly.

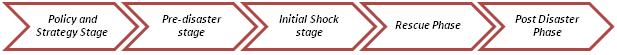

STAGES OF DISASTER

A. Policy and Strategy Stage

This is the pre-disaster stage, it will include building up of strategy and capabilities to counter and mitigate disaster situations. This will include formation of joint management teams which could act as the decision making back-bone of all rescue and resource gathering activities during disaster. A central command will be set up, which acts as the central body for information gathering and semi-automated tactical decision making during disaster. Since, this is pre-planning stage; our major focus here is to come up with cost effective and reliable systems.

B. Pre-disaster stage

Most of the natural disasters can be predicted through early warning systems e.g. floods, typhoons and cyclones. This stage starts as soon as such a trigger happens till the time the disaster actually strikes. The basic aim is to mitigate the disaster or atleast lower its effect by early evacuation through efficient use of supply chain capabilities. Due to the criticality of time during this stage, our major focus in this stage is rapid response and cost issues are redundant.

C. Initial Shock stage

It starts from the point when actual disaster starts and continues till the rescue teams are deployed and rescue systems start acting. A quick response here can cause a significant life saving in the later stages, since only after this stage real rescue begins. Hence, it is pertinent to use faster means of deployment such as air-dropping of relief material & rescue teams. Since, real-time data about the disaster is highly volatile and unreliable; hence we base our estimates of requirements on topographic & demographic data available to us. Also, for time being locally available resources are included in our estimates only if we are sure of its existence post-disaster.

D. Rescue Phase

This stage signifies commencement of fully fledged rescue operation from the on-ground staff with the help of local resources and authorities. The real time data is collected through mobile vehicles having VSAT facilities and transmitted to central command for further routing of relief efforts. The supply chain is setup to get the requisite rescue materials from outside as well as inside the disaster zone. The local centers start distribution of rescue material and services, ex. medical services and water treatment etc.

E. Post Disaster Phase

This is marked by relocation of people from rescue camps to their original or alternate habitat. This is a longer stage and cost considerations are important here. This stage is marked by massive reconstruction and proper supply chain and public-private partnership plays an important role in this phase. Also, at the central command level this stage is marked by policy and strategy refinement based on the feedback on their effectiveness in dealing with on-ground situation.

MAJOR COMPONENTS OF SUPPLY CHAIN

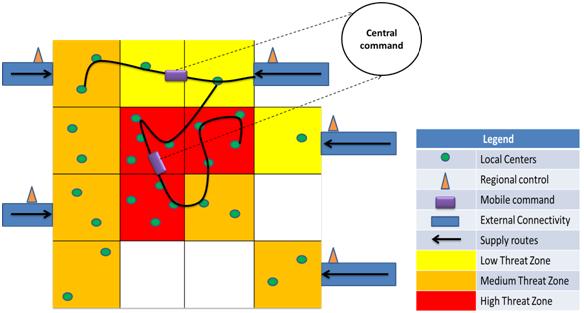

A. Central command

It acts as the backbone for information collection, analysis and semi-automatic operational and tactical decision making system. It will be equipped with sophisticated computing facilities, direct link to early warning system and satellite earth station. Mobile vehicles and regional controls shall upload the data to central command through different media. Basing these inputs, command shall prepare distribution & transportation plan and guide rescue personnel to the point of real need. Center shall have experts such as meteorologists, geologists, statisticians, IT personnel and SCM & disaster management professionals.

B. Mobile Command

Mobile command will be in the form of Mobile vehicles having robust data gathering and communication facilities including VSAT and GPS. It will act as the information link to the outside disaster zone. The primary functions of mobile command are gathering data related to rescue requirements, transport link failures and personnel deployment. It will additionally act as a watch-dog for all rescue efforts and will send daily reports on the amount of rescue materials received at each local distribution center and will take random feedback from people inside and outside rescue camps.

C. Regional Centres

These are warehouses located on the periphery of disaster areas and strategically located on the intersection points of main rail/road links. This is the point where we can conduct a system check on total relief material received and dispatched to a particular zone vis-à-vis the actual assistance received by the stakeholders. The regional system shall update the central command with vital data regarding relief & construction material, man-power requirement, vehicle deployment and resources required. The centre shall perform following functions:

• Receiving, sorting, packaging, inventorying, storing and dispatching relief material and other items

• Physical verification of supplies for quality, quantity, lot size and type

• Routing of vehicles and controlling the movement, transmitting data to central command

D. Local Centres

Local team comprising of trained villagers, nurses etc will look after smooth operation of the center, while the members of central team (doctor, evacuation expert etc) will maintain an overview and collect data for future needs and conduct situation analysis to help the central command allocate resources with high precision.

SUPPLY CHAIN

A. IT infrastructure system:

Central command shall control the flow of information in and out of the system. It will provide information to the regional centers, mobile command and local centers through different communication media. The level of information sharing will be different for different levels, for example- central command will carry-out a radio broadcast to ensure mobilization of work-team at local centers. The regional centers shall update the central command with warehouse inventory, goods on wheel, location of vehicles and level of deployment and future needs if any. This will help command centers to optimize the use of available resources and reach out to wider areas.

Local centers will be provided with support depending upon the requirement they quote and the assessment of mobile command. Independent verification is important, as people overestimate requirements during disaster and resultant information asymmetry derails supply chain system.

B. Movement of Goods and services

Flow of goods shall be controlled centrally but the physical movement of goods shall not be routed through the central command in order to avoid bottlenecks and unnecessary diversions. We plan to commission regional centers on the periphery of disaster area, strategically located near major rail/road route to minimize the transportation needs. The regional center shall be performing sorting, inventorying, repackaging, warehousing, distribution and transportation planning of that region. We shall have our own specialists there to assist the operators. The operational control can be given to 3rd party and/or 4th party logistics service provider who are having sufficient local knowledge.

The regional system shall update the central command with vital data regarding relief & construction material, man-power requirement, vehicle deployment and resources required.

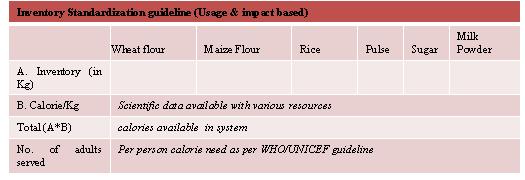

INVENTORY CATEGORIZATION & REQUIREMENT CALCULATION

Individual donors, NGOs, government agencies and international relief agencies (UNICEF etc) contribute relief materials and it is difficult to categorize & maintain inventory of each items separately. To ensure that correct level of relief is dispatched, we propose codification of relief material as per the impact & usage. WHO (or UNICEF) guidelinesmustbe followed to benchmark calorific content of food materialswith respect to per person energy requirements. It will help us quantify the available resources and forecast future needs.

Below table is an example of such standardization:

LOGISTICS CAPACITY CALCULATION:

This methodology helps in formulating a universal system of estimation of transport facilities based on capacity (no.of persons/ kg’s of material) and speed of the medium. For example, if in a disaster we are supposed to rescue 100 persons situated at a distance of 25 km from relief center, given either a bus with capacity of 25 and average speed of 50km/hr or a bullock cart with capacity of 10 and speed of 12.5 km per hour. We need 4 bus trips and same bus can be deployed. In case of bullock cart, same cart can’t be deployed twice, due to speed constraints, so we require 10 carts. So, effectively, 10 bullock carts are only as effective as 1 bus, due to slower response.

Hence the model first looks at the feasibility of usage of a particular medium of transport with respect to the speed and the distance to be covered. As outlined earlier, if the distance were more than 50km, bullock cart would have proved useless. Hence only after conducting the feasibility analysis of the medium, does the model capture its capacity in resource estimation. Hence, this methodology helps us to use locally available limited capacity transport facilities.

TRANSPORTATION SYSTEM INCLUDING 3 PL, 4 PL

We propose a multimodal system for transportation. We shall use rail, road, water and air route to reach out to the end point. Our model shall provide scope for the usage of trucks (including containers), goods train, boat, helicopter and other traditional carriers such as bullock cart to prepare a robust and fail-safe logistics distribution system. Transportation planning shall incorporate reverse logistics to ensure better optimization.

We intend to meet the vehicle requirement through two sources:

External- Directly hiring vehicles from open market on short term/long term contracts

Internal- Leveraging government & NGOs and deploying locally available vehicles to ensure faster response

Fuel: Fuel shortage can paralyze the whole distribution system and we intent to maintain sufficient inventory on wheels (oil tankers) and in regional warehouses to meet such demand.

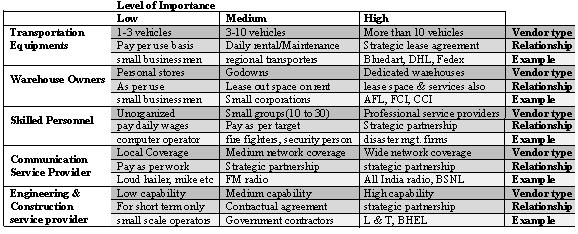

VENDOR MANAGEMENT AND CLASSIFICATION OF THIRD PARTY RESOURCES

Channel partners play vital role in ensuring correct implementation of supply chain model. Early identification of suitable partners, forging relationship and assigning responsibilities is important. As we moves through different phases of the disaster management, our focus shifts towards cost control and resources optimization.

We have defined a vendor role & relationship matrix:

LIMITATIONS

Although the model is robust and provides a generalist approach towards managing supply chain in different disaster situations; a particular case might demand unique set of requirements. Hence, the model should be used as a reference to prepare specific plans such as flood relief, earthquake and terrorist attack. Difference in topography is another factor which impacts the supply chain system directly. For example, Indian forces’ disaster supply chain system for Siachin glacier point will require highly customized medical equipments and transportation vehicles.

ASSUMTIONS

• Central command has practically unlimited access to qualified personnel, information system and subsequent back up, considering the fact that the centre is located well outside the disaster zone.

• Government & NGO’s facilities and capabilities are utilized during disaster. However, this is not always the case and should be factored in while designing the supply chain system.

• Role of private corporations is not outlined, but same can be leveraged if such help is offered by private enterprise.

CONCLUSION

Supply chain systems for disaster management require correct channelization of vast pool of resources. To meet this end, we first defined the need-set for different types of disaster and mapped it against the resource availability. It helped us design a robust system which is applicable to variety of disaster situations. We understand that basic pillars of any efficient supply chain for disaster management are – information management, reliable channel partners, relevant physical resources and robust back up mechanism. Defining and demarcating duties & responsibilities of channel partners is necessary to ensure frictionless operations during disaster. Role of supply chain & disaster management experts cannot be undermined; as they have the experience of managing such situations. We figured that post disaster supply chain management is equally critical which is usually neglected by planners; resulting in prolonged effects of disaster. Finally, correct & timely implementation of the plan along with cost-control & quality audits is the desired goal.

REFERENCE

[1] International Strategy for Disaster Reduction , http://www.unisdr.org retrieved on 12th Feb 2011

[2] Disaster Management In India -A Status Report, August 2004, Government of India

[3] http://www.ndmindia.nic.in/, retrieved on 01st Feb 2011

[4] Draft guidelines on disaster management, 2006, Telecommunication Engineering Centre, New Delhi

[5] Recovery after Disaster: Achieving Sustainable Development, Mitigation and Equity, Berke Philip R., Kartez Jack, Wenger Dennis, Disasters (Journal),Volume 17, Issue 2, June 1993

[6] Disaster, http://www.icm.tn.gov.in/dengue/disaster.htm retrieved on 13th Feb 2011

[7] Resilient supply chains for extreme situations. BoinArjen ,Kelle Peter,Whybark D. Clay,International Journal of Production Economics, Volume 126, Issue 1, July 2010

[8] Wal-Mart at Forefront of Hurricane Relief, Barbaro Michael, Gillis Justin, Washington Post, September 6, 2005

This article has been coauthored by Mayank Kamal and Puneet Singh from IIM Lucknow

Views expressed in the article are personal. The articles are for educational & academic purpose only, and have been uploaded by the MBA Skool Team.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us