- Articles ›

- Operations and IT ›

- Bottlenecks: A recipe for manufacturing death Articles

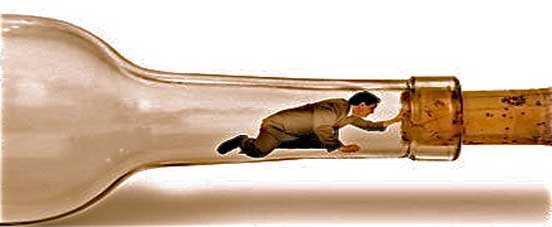

Bottlenecks: A recipe for manufacturing death

For manufacturing plants to be successful, it is important for them to be organized. To ensure production of quality products at a continuous pace, it is utmost significant that they have latest techniques, problem solving skills, defined layouts etc. The use of latest machinery and precision equipment coupled with management information systems, benefits the organizations in ensuring continuity of production. But inspite of having the best resources, skills and techniques, there is one critical factor which can cause tremendous chaos and trouble in the process - Bottlenecks.

Avoiding bottlenecks is critical for any production unit to ensure that speedy manufacturing is achieved. This is because bottlenecks affect the smooth process, thereby causing a severe mismanagement of resources, delaying time and affecting the throughput. The entire processing and planning goes for a toss and affects the ability to have just in time processes.

Production bottlenecks can be compared to an example, which all of us experience in our day to day lives. Traffic jams and slow moving vehicles due to varying widths of roads is very much a similar problem of bottlenecks as compared to manufacturing units. Expansive patches on the roadways cause a free and fast flow of traffic but a sudden narrow patch causes cramping of vehicles, leading to blockages in traffic. Adding to that, individuals looking for ways to break though the traffic by meandering through the gaps, further entangles the situation. All these can be avoided by either having a controlled traffic management and limiting of vehicles on the basis of priority, or by having alternative routes like flyovers to bypass the traffic. By doing so, an effective flow can be obtained inspite of irregular road widths.

Applying the same phenomenon to manufacturing organizations can be hugely beneficial. The most important factor in avoiding and reducing bottlenecks is to prioritize your resources effectively, and ensure just in time processes for supplying to the next stage. Companies should look for long term solutions for tackling bottleneck problems rather than going for short term shortcuts. They should have a perspective for future scope as well, so that expanding processes further doesn’t lead to any blockages. Apart from process control, man control is also essential in tackling the problem of bottlenecks.

In this fast paced competitive market, continuous processes are the keys to success for any manufacturing plant, so as to effectively meet the demands of the consumer. But these can be severely disrupted by bottlenecks in the production chain, thereby gradually stifling the business to a cruel death.

The article has been authored by the editorial team. The content on MBA Skool has been created for educational & academic purpose only.

If you are interested in writing articles for us, Submit Here

Share this Page on:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

All Business Sections

Write for Us