- Business Concepts ›

- Operations and Supply Chain ›

- Distribution Resource Planning (DRP-II)

Distribution Resource Planning (DRP-II)

Definition & Meaning

This article covers meaning & overview of Distribution Resource Planning (DRP-II) from operations perspective.

What is meant by Distribution Resource Planning (DRP-II)?

Distribution Resource Planning (DRP-II) is an extended version of Distribution Requirement Planning (DRP-I). Distribution Requirement Planning is a process which is used to determine which goods or materials will be required at which location and at what time to meet the anticipated demand.

DRP-II includes maintaining the provision for major non-inventory items and resources such as labour, material handling systems, and storage space. It may include other resources such as finances, trucks, freight cars, etc. This information is then entered into an MRP-II ( Manufacturing Resource Planning) as gross requirements for estimating and calculating input flows and preparing the schedules of production activities.

The main goal of DRP-II is to eliminate or at least minimize the shortages and at the same time, reduce the costs incurred during ordering, transporting and storing or holding goods. It is also called as Distribution Replenishment Planning. It is a time based approach which estimates when inventory is expected to be depleted and accordingly replenishes the same on time.

It follows a tree-like approach wherein a central facility like a warehouse is connected to several regional facilities and supplies goods to them who in turn pass them on to other facilities in the hierarchy.

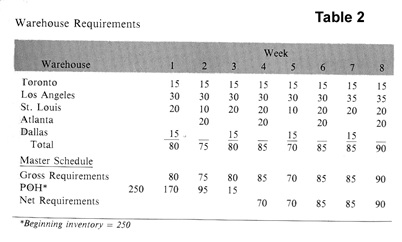

DRP Table forms an important constituent of the DRP-II mechanism, It includes several elements like:

i) Forecast demands

ii) Current inventory levels

iii) Safety Stock

iv) Expected Replenishment Quantities

v) Replenishment Lead Times

DRP-II works either with the pull or push approach. In the pull method, goods are moved up the network by fulfilling the customer orders. This is a localised approach and as such, customer demands are met in a better way. However, managing the inventory is an issue in this method. In the push method, goods are sent down through the network. It incurs lower costs due to centralised planning and storage of goods. Disadvantage of the push method is service levels can be affected if central planning is unaware of the actual demand. DRP-II ideally envisages to combine the efficiency of push with the service levels of pull.

The table shown above clearly shows how Distribution Requirement Planning is carried out.

Hence, this concludes the definition of Distribution Resource Planning (DRP-II) along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us