- Business Concepts ›

- Operations and Supply Chain ›

- Capacity Management

Capacity Management

Definition, Importance, Types, Process & Example

This article covers meaning & overview of Capacity Management from operations perspective.

What is meant by Capacity Management?

Capacity management is the process of managing the production output required depending on the demand & supply conditions to make sure that the business optimizes its capacity to the fullest. Capacity management is the ability to meet the customer demand with the available resources like machinery, factory, labour, raw materials etc.

Importance of Capacity Management

Without proper analysis and management of a company's capacity, it would be very difficult to create a sustainable business model. Either the business would not be able to meet the demand or it will end up having more capacity than required incurring losses.

Capacity is the total amount of final goods a company can manufacture in a certain time period. Generally, the required outputs during manufacturing resource constraints are met by working overtime or redeploying the workforce.

Capacity planning is done on the basis of projections for future product demand, labour and equipment requirements. Time and Capacity are the two main constraints in capacity management.

When a customer has provided a deadline, managers have to plan backwards. This is when production schedules come into the picture. There are two types of schedules:

1. Job Schedule – Manufacturing plan for a particular job

2. Production Schedule – Joining several job schedules(tasks) to arrive at a production plan

These are very important in making sure that capacity is well managed and also meets the demand fluctuations.

Read More

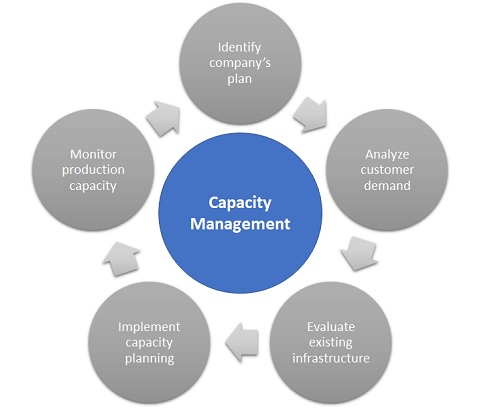

Capacity Management Process

The process includes the following steps:

1. Identify company’s future plan

The opportunity pipeline and forecasts would help in knowing the demand for production in the coming days and months so that the capacity can be effectively managed. If more people are needed to hired or machine maintenance is required to match the upcoming demand.

2. Analyze customer demand & opportunities.

A company needs to understand the customer demand and market trends through which again the opportunity pipeline would be created. Also need to see if some events or seasonality can affect customer demands.

3. Evaluate output of existing infrastructure and resources.

Before increasing the production as per new plan, organization needs to see if the current infrastructure and resources would be able to manage the production. If not, new machines may have to be leased or procured. Also more manpower might be required to operate them. Quality control has also be managed well. Increased production should be of the highest quality.

4. Implement capacity planning depending on decision

After the plan, implementation and execution has to be done. If the decision is to add more machines and increase production, then the plan has to be implemented by getting the new machines, installing them and start the production to match the demand and orders.

5. Constantly monitor & review production capacity

Constant monitoring and feedback is very important in capacity management. After the plan is made and implemented, the company needs to constantly review the processes. Like any good process, capacity management is an ongoing process and there always a scope for improvement.

Types of Capacity Management

Three types of capacity which needs to be managed:

1. Potential Capacity

It is for the long term and indicates the available capacity at hand which can be utilized to influence the planning of senior management

2. Immediate Capacity

It is the maximum available capacity which can be utilized in the short term ( on a day-to-day basis)so needs to be managed immediately

3. Effective capacity

It is the part of the total available capacity which can actually be put into use.

Capacity Management Example

Let us take an example of a television manufacturer. Now the company always need to make sure that they are able to meet the demand. Now the company forecasts that the TV demand may go high as football world cup is going to start in 6 months time.

Now the managers would estimate the number of TV sets which would be sold as per the new demand and also it is observed that HD televisions would be in more demand. Next step would be too see if the current capacity is more than enough to product the additional demand for televisions or not.

As per the analysis, they might need more capacity and manpower to handle the demand but then the demand is expected to go down immediately once the world cup ends, so the company would want to lease the machines rather than buying new which may be under utilized later.

Once the lease is secured and manpower is recruited, the production would start 2-3 months before the event so that televisions can reach the retail channels when the demand rises.

Hence, this concludes the definition of Capacity Management along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us