- Business Concepts ›

- Operations and Supply Chain ›

- ABC Analysis

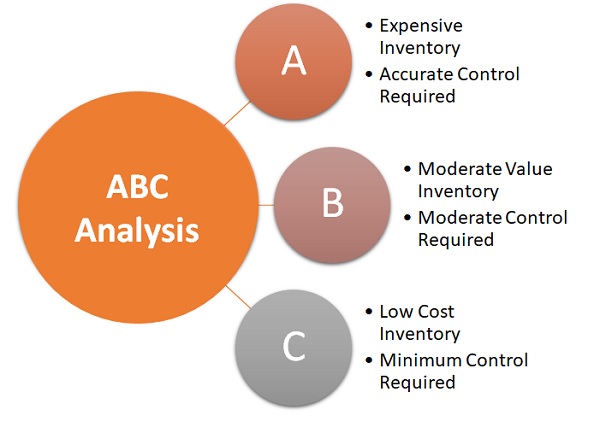

ABC Analysis

Definition, Importance & Example

This article covers meaning & overview of ABC Analysis from operations perspective.

What is meant by ABC Analysis?

ABC analysis is a method of categorization of inventory based on significance and importance of the items in the production process which determines the level of inventory control. It is defined as a method of classifying clients, events, inventory, items or activities according to their relative significance and deciding upon this fact that on the extent of importance, consideration and control one should put on this analysis under such classifications. ABC Analysis comes under the purview of inventory management.

Importance of ABC Classification

It’s a ranking system where items are grouped according to their usefulness in achieving in business goals. This system requires grouping of things into 3 different categories:

A – Most Important

B – Very Important

C – Important

Purpose of doing this ABC classification is identifying things which effect output the most. Low variation in these things can lead to high changes in output. Thus these things are closely monitored thus helping organizations to increase their efficiency.

As A category things are more important more attention is given to A and relatively less to B and C. One should use it for selection of a restricted number of tasks or clients because it produces significant overall result or profit. It basically uses the idea that by doing 20% of effort, 80% of the gain of doing the entire work can be generated. For many events, about 80% of the things come from 20% of the causes.

This analysis works under the assumption that all inventories are not of equal value to the organization so they need to be treated differently. A typical ABC analysis classifies the inventory based on the following table.

|

Type of Inventory |

Type of Importance |

Type of control |

|

A Items |

Very Important |

Accurate records, very tight control |

|

B Items |

Little less important |

Decent records, a little less tight control |

|

C Items |

Marginally important |

Only essential records, light controls |

Typically “A items” consist of minimum amount of items but these items account for a major proportion of value for the organization and so on with the other items.

Read More

Advantages & Disadvantages of ABC Analysis

Some advantages are:

1. Better control on expensive items on which large investment is required

2. Cycle counting, which is an indicator of stock replenishment can be effectively used after completing the grouping

3. Ensures reduction in storage expenses

However, some of the drawbacks of this method are:

1. This method can’t be employed where products can’t be standardized

2. Classification is done purely on the basis of monetary value and other factors are ignored

3. A good system to codify the products should be used in order to perform the ABC analysis

Example of ABC Analysis

In an inventory management system we can categorize products into ABC classification depending upon their annual sale or percentage sale of the items. High selling items should be categorized as A and managing their inventory should be top priority of inventory management team. A group of items might only be 20% of various types of products available but their business importance or contribution to revenue is 80%.

Hence, this concludes the definition of ABC Analysis along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us