- Business Concepts ›

- Operations and Supply Chain ›

- Production Scheduling

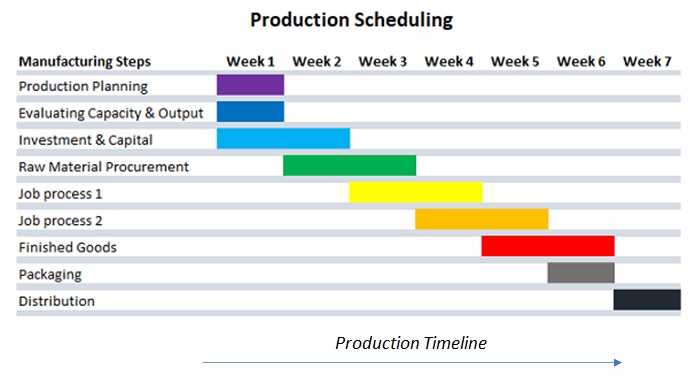

Production Scheduling

Definition, Importance, Steps & Factors

This article covers meaning & overview of Production Scheduling from operations perspective.

What is meant by Production Scheduling?

Production scheduling is the process in manufacturing where all production activities are planned or scheduled on a timescale or for a time period. Production scheduling includes planning manufacturing activities like procuring input goods, investment, labor, logistics etc for a specific time period in a sequential manner. It identifies that what resources would be consumed at what stage of production. According to the estimates, a time-based schedule is made so that the company does not fall short of resources at the time of production.

Importance of Production Scheduling

The production schedule prepares in-depth estimates of future cash flow also to identify the requirement before taking up a project. Production scheduling tries to optimize the use of the manpower so that there are no excess manpower or shortage of manpower during the production process.

Production scheduling was traditionally done manually using paper and later organizations started using spreadsheets and now a no. of different software’s are available for the same. In production scheduling the process usually starts with the identification of the deadline and then moved backward to the current date and in the process the bottleneck processes are identified. Production scheduling takes into account all the constraints like capacity, manpower, Inventory, Plant floor throughput and tries to optimize their use.

Production Scheduling Factors

Some of the key factors which determine the schedules of production are:

1. Total goods to be manufactured for sale or additional storage

2. The amount of labors at disposal.

3. Capital invested & expected timelines for sales.

4. Time from manufacture to packaging to distribution to sale.

5. Capacity & capability to machinery.

Production Scheduling Steps

A good product schedule can be created following these steps:

1. Production Planning

A good production schedule starts with proper planning. Without planning a schedule cannot be created. A schedule needs activities, sub-processes, assumptions etc. to be properly known before a timeline is created.

2. Smart Routing

Routing is required to show the entire journey of a product from its conversion from raw material to final finished product. In the schedule, the transfer from one department and another has to be known. Swim-lane diagrams can be used to show the transfer of ownership.

3. Actual Scheduling

This is the most important step with all the timelines with activities. This should be made as modular as possible. The production schedule should be customized based on different parameters like the size of the batch to be produced. configuration, parts and processes etc.

4. Execution & Development

This is the step where the production schedule actually becomes the real time process. The production of goods is done through the schedule prepared. The first 3 steps act as steps or instructions to start the execution smoothly.

5. Continuous Improvement and Rescheduling

Like any good process, feedback and variances should be closely monitored and used to further improve the production scheduling process for the next cycle. The feedback can be automated or can be manually handled. The ultimate goal is make the process better every time.

Hence, this concludes the definition of Production Scheduling along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us