- Business Concepts ›

- Operations and Supply Chain ›

- Assembly Line

Assembly Line

Definition, Importance, Types & Example

This article covers meaning & overview of Assembly Line from operations perspective.

What is meant by Assembly Line?

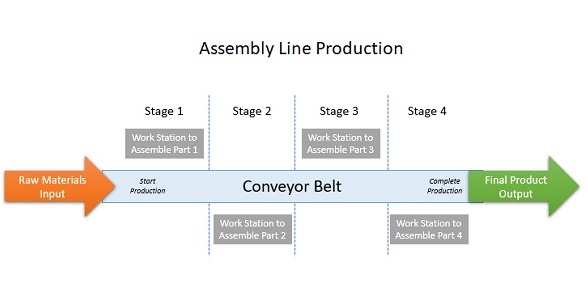

Assembly line is a process in manufacturing for production of goods where smaller products are assembled at different steps in a sequence to produce the final product. In assembly line production, the main product moves from stage one to the end stage in a defined sequence. In most cases, an assembly line is a partial automated process, and at each stage there might be a human intervention. Assembly line is very common and mostly seen in manufacturing industries. It is very commonly seen in the automobile manufacturing where in automated robotic arms assemble a complete car in a sequence of pre-defined steps.

Importance of Assemble Line

Manufacturing of goods or products is a lengthy process as it requires several smaller parts to be assembled together. Smaller parts when attached or assembled in a particular sequence of stages leads to formation of the finished product. Assembly line production ensures that there are multiple stages defined in the manufacturing process, and at each stage a smaller part is attached. Once all stages are completed, the finished product or the assembled product is created.

The workers at every stage at stationary and are experts at assembling their small part. The line or the conveyor belt is used to take the product to the next stage.

Assembly line production is an important mechanism to have increased productivity and maximize efficiency of the product being manufactured. A streamlined manufacturing process enables workers to work in tandem at their respective stage. Use of a conveyor belt or line ensures that the product is taken to every subsequent stage for assembly of the next smaller part.

Read More

Types of Assembly Line Methods

Depending upon the arrangement, design, stages, production need etc there are different ways to have assembly line production processes. Some of them are:

1. Modular process

This process involves having parallel assembly lines producing multiple smaller products simultaneously.

At the end of each assembly line, all lines or smaller products are merged to produce the finished final product.

2. Cell Manufacturing

This method of assembly line uses machines which can perform multiple tasks at a single stage, rather than having a separate stage for every step required.

3. Team production

This method involved teams to participate at different stages & final quality check stages to ensure that the finished product is of high quality.

The different teams are responsible and accountable for their own set of steps within a stage and then handover to the next team.

4. U Shaped Assembly Line

In this method, instead of a straight line of production, there is a U shaped or curved line, where workers stand between the curves. This ensures better communication between adjacent stages of production.

Advantages of Assembly Line

Some benefits of using assembly line production are:

1. Time to manufacture goods have reduced.

2. Higher efficiency of output as each stage is driven by an expert worker.

3. Assembly line enhanced by concepts like JIT or just in time ensure a streamlined, smooth & continuous flow of production.

4. People management has become easier as each worker has their role clearly defined and is unique from other workers working at different stages of production.

Assembly Line Example

A very common and well known example is car manufacturing where a lot of parts are assembled one by one to create the final automobile. The process can start from engine fitting and then the car moves to chassis assembly. From there it is moved to a stage where the overall car body is assembled through various operations including doors, windows etc.

Then next step can be painting and coating the car with required color before it moves to installation of seats and other interior instrumentation. After that other final things can be assembled and completed before the car can go in testing stage.

Hence, this concludes the definition of Assembly Line along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us