- Business Concepts ›

- Operations and Supply Chain ›

- Capacity Utilization

Capacity Utilization

This article explains definition, importance & example of Capacity Utilization from operations perspective.

Capacity Utilization Definition

Capacity utilization is the fraction of the total capacity which is used for production within a given interval of time. Capacity utilization is the ratio of the actual output to the maximum possible output & is expressed in percentage.

Importance of Capacity Utilization

A firm possesses a definite set of resources at its disposal. This enables the firm to produce a certain number of products or provide a certain amount of service in a given period of time. This ideal, maximum capability of the firm is called its capacity. However, in actual scenario, this capacity is not fully used at all the time. The amount of production capacity actually used is the capacity utilization of that task or firm.

Usually this is less than 100%, whereby the firm is said to operate at ‘under-capacity’. 100% implies ‘full capacity’ and greater than 100% implies ‘over-capacity’. Main reasons behind such fluctuations are:

1. Seasonal demand

2. Varying market share due to increase / reduction of competition

3. More / less successful marketing

Though under-capacity generally implies less than ideal performance of the firm, full and over-capacity operations yield problems like less maintenance time, greater employee (and machine) fatigue due to over-time, etc.

Read More

Formula for Capacity Utilization

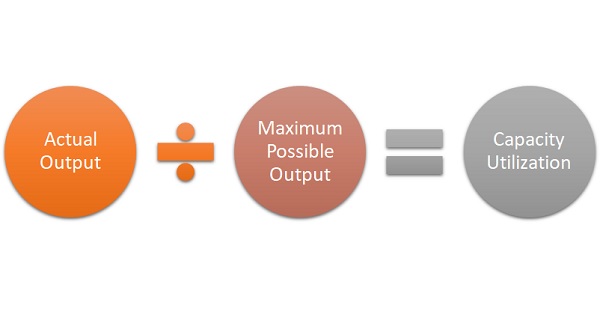

The formula to calculate the capacity which is being used is:

Capacity Utilization = (Actual Level of Output / Maximum Possible Output) x 100

This is calculated for a specific time period.

Example

Consider a company which can produce a maximum 1000 units of a product in an hour. At a normal capacity of production, the company produces only 600 units. Thus, capacity utilization is:

(600 units / 1000 units) x 100 = 60%

Hence the company operates at 60% capacity utilization per hour.

Hence, this concludes the definition of Capacity Utilization along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us