- Business Concepts ›

- Operations and Supply Chain ›

- JIT (Just In Time)

JIT (Just In Time)

This article explains definition, importance & example of JIT (Just In Time) from operations perspective.

JIT (Just In Time) Definition

JIT or Just in Time, is system in operations management under which the production is made as per the demand at that particular moment. There is no prior production for any anticipated demand. Under JIT, the manufacturing process is highly efficient with limited wastage, high quality control, adherence to schedules & a seamless continuous throughput.

Importance of Just in Time

The aim is to reduce non profitable activities and make the manufacturing system more flexible, eliminating the associated costs of carrying and maintaining the inventory. There is no scope for extra inventory what so ever. This was pioneered by Toyota at their facility.

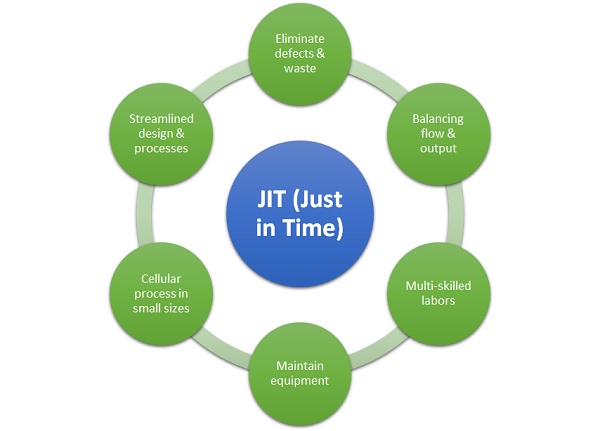

JIT Methods

There are various methods in which just in time or JIT can be achieved. However, all these methods are important but not exhaustive:

1. Elimination of defects & waste

2. Balancing the flow and scheduling the output

3. Multi-skilled labor force to carry out specific operations

4. Maintenance of equipment and machinery for flawless operations

5. Cellular manufacturing i.e. making in small batch sizes.

6. Streamlined design and process flows & layouts

Advantages of Just in Time

There are several advantages which have been beneficial for organizations who have adopted JIT. Some of the advantages of JIT are mentioned below.

1. Reduced setup time and low wastage.

2. The flow of goods from warehouse to shelves improves.

3. Employees with multiple skills are used more efficiently.

4. Increased emphasis on supplier relationships.

5. Minimizes storage space needed thereby saving warehousing costs.

6. Smaller chance of inventory breaking/expiring.

JIT Examples

Some examples of companies using JIT techniques to increase business efficiency are:

1. Nike has manufacturing units spread across the world, with all different locations performing activities by their own processes. Nike then centralized all the global units with CRM & supply chain management software. With continuous monitoring of all stages of production, JIT enabled Nike company to increase productivity, faster production times & decline in lead times.

2. Dell computers is a prime example of using just in time technique. For its customized laptops & personal computers, Dell only placed order of spare parts once a customer confirmed the orders. Hence there was minimum inventory storage, thereby reducing inventory costs & lead times.

Hence, this concludes the definition of JIT (Just In Time) along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us