- Business Concepts ›

- Operations and Supply Chain ›

- Batch Production

Batch Production

Definition, Importance & Example

This article covers meaning & overview of Batch Production from operations perspective.

What is meant by Batch Production?

Batch production is a production methodology in which products are manufactured in groups called batches rather than in a continuous fashion. In batch production, a group or set or batch of products are made, and the same machinery is used to make the next batch of goods. Batch production is usually used for making group orders, and not used for mass production.

Importance of Batch Production

Batch production is one of the three primary forms of manufacturing, with job and flow being the others. While job system is used in cases where high level of customization is required and flow is used where the same product is to be mass produced, batch production system offers flexibility in terms of these two factors. It allows customization to some extent in order to meet specific customer needs while ensuring higher productivity than a job based system.

To reduce changeover time between batches, jigs and templates are generally used. The time taken between consecutive batches is known as cycle time.

Read More

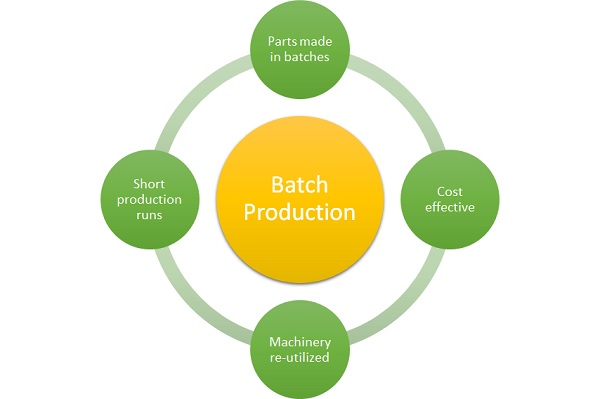

Characteristics of Batch Production

The certain elements of batch production are as mentioned below:

1. Reuse

The same machinery can be re-utilized for producing another batch of products which may be same or can have minor changes like color, size or shape

2. Group Customizations

Customizations can be done at a group level in batch production. In batch production, the customization related to minor changes can be done in groups to produce batches as per production plan and market demand.

These group customizations make the batch production a more viable option and responsive to changing demands.

3. Batch Size

Parts or products are made in smaller batches. These smaller batches are beneficial because the time taken is less and also the quality control can be done in a more efficient way.

4. Cost Effective

It is cost effective as compared to every customized job production product. Batch production because of its reusability and better quality control is a more cost efficient method as compared to continuous manufacturing.

Advantages & Disadvantages of Batch Production

It reduces cost as a single production line can be produced to manufacture different products with slight modifications while use of specialist machinery and skills can increase the output and productivity.

However, it has certain disadvantages as well viz. the switching time lost in changing jobs and large work in process inventory leading to inventory costs.

Examples of Batch Production

1. Batch production techniques are generally used in Baking or meal preparation. Consider a bakery using its over to bake 50 white breads in the first batch. Then the same oven can be used to bake 50 brown breads. Also, after this 30 buns can be baked. Hence the same machinery is used for making different group of products in batches.

2. Manufacturing clothes also use batch production. Consider a t-shirt manufacturing company. In its first batch, it makes 100 blue t-shirts, followed by 100 green & 100 red t-shirts in the subsequent batches. All these t-shirts are made using the same machinery, just by tweaking the colors & machinery.

Hence, this concludes the definition of Batch Production along with its overview.

This article has been researched & authored by the Business Concepts Team which comprises of MBA students, management professionals, and industry experts. It has been reviewed & published by the MBA Skool Team. The content on MBA Skool has been created for educational & academic purpose only.

Browse the definition and meaning of more similar terms. The Management Dictionary covers over 1800 business concepts from 5 categories.

Continue Reading:

What is MBA Skool?About Us

MBA Skool is a Knowledge Resource for Management Students, Aspirants & Professionals.

Business Courses

Quizzes & Skills

Quizzes test your expertise in business and Skill tests evaluate your management traits

Related Content

All Business Sections

Write for Us